Ships on wheels

A whole 200 heavy-duty axle lines with 1,600 wheels were used by the specialist Hareket to move two passenger ships from dry dock to floating dock at the Turkish Tersan shipyard. Read more

The encapsulated and stepped design guarantees maximum running performance and availability. And thanks to the use of DIN-ISO tapered roller bearings, it beats the competition hands down in terms of ease of maintenance and repair.

Thanks to its robust design and incomparable ease of servicing, the ECO Drum sets standards in terms of life cycle costing. A powerful all-rounder with the lowest wear.

With KTL+ZN coating, the best surface protection is guaranteed.

With KTL+ZN coating, the best surface protection is guaranteed.

The encapsulated and stepped design guarantees maximum running performance and availability. And thanks to the use of DIN-ISO tapered roller bearings, it beats the competition hands down in terms of ease of maintenance and repair.

A whole 200 heavy-duty axle lines with 1,600 wheels were used by the specialist Hareket to move two passenger ships from dry dock to floating dock at the Turkish Tersan shipyard. Read more

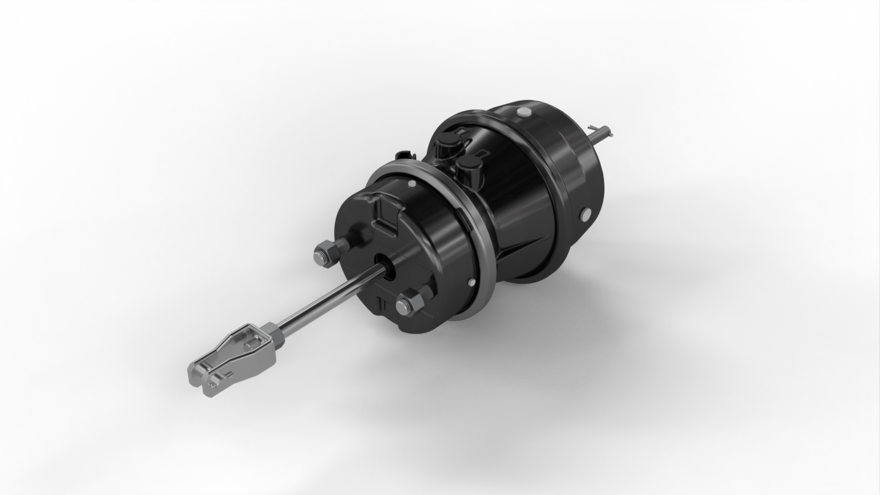

In a brake system, the optimal interaction of the individual components is of the utmost importance. The brake cylinders play a decisive role here, because they have to ensure perfectly dosed power transmission in the braking system. Brake cylinders from BPW are further proof of our comprehensive expertise when it comes to brakes. As a system supplier, our product range includes diaphragm and spring-loaded cylinders.

Due to its function, the advantages of the self-steering axle have so far only come into play when driving forwards. When driving backwards, the steering mechanism is locked and the axle remains rigid. With ARC (Active Reverse Control), you can now also benefit from the advantages of a steering axle when driving in reverse. Because with ARC, BPW has developed an electrohydraulic auxiliary steering system that steers the steering axle fully automatically when reversing at a speed of up to 10 km/h. This increases agility and manoeuvrability. This increases the agility and manoeuvrability of your vehicles when reversing and reduces time and tyre wear!

As an important control instrument, the BPW capsule with integrated hubodometer records the mileage of your trailer. Especially with changing motor vehicles, you can always see the actual vehicle mileage.

The BPW drawbar support is particularly light and therefore the first choice when every kilo of payload counts! Thanks to long-term lubrication with BPW ECO Li 91, the BPW landing gear is maintenance-free for three years. It also impresses with minimal wear and tear and is optimally protected against corrosion by the high-quality coating.Just right for tough use in the trailer, thanks to a reinforced shaft for absorbing lateral forces and a continuous bolt-on plate for optimum strength. And all with built-in safety: BPW support devices meet the requirements of the AAR. The long, continuously perforated bolt-on plate for various bolt-on positions enables simple and flexible installation. Low crank forces make daily work easier.

Turntables enable 360-degree turning movements by means of two steel rings that are connected to each other by means of ball bearings. BPW turntables are used where vehicle construction places the highest demands on design and material. Compared to conventional single-row systems, BPW turntables differ due to the quality feature of the double row of balls: The design superiority is that the additional second row of balls ensures optimum distribution of the axial and radial forces that occur.